How WMSOne is the best Warehouse Solution in Botswana

- Why WMSOne Stands Out In Warehouse Management - December 30, 2024

- The Future of Warehouse Inventory Management in 2025 - December 9, 2024

- Cold Storage Warehouse: Keeping Food Fresh And Safe - October 3, 2024

Introduction

WMSOne Became the Premier Warehouse Solution in Botswana. In the heart of Southern Africa, Botswana’s burgeoning logistics sector faced a significant challenge: managing warehouse operations with the efficiency and precision required to support its growing economy. Enter WMSOne, a cutting-edge warehouse management system (WMS) that transformed the way businesses in Botswana manage their inventory, optimize storage, and streamline supply chains. This case study explores how WMSOne became the leading warehouse solution in Botswana, revolutionizing the logistics landscape.

Background

Botswana’s strategic location as a gateway to the Southern African Development Community (SADC) made it a crucial hub for trade and logistics. However, with this strategic advantage came the challenge of managing increasingly complex warehouse operations. Traditional manual methods were no longer sufficient to keep up with the demand for speed, accuracy, and efficiency. Businesses needed a solution that could offer real-time visibility, enhance operational efficiency, and reduce costs. WMSOne emerged as the answer.

Challenges

- Manual Inventory Management: Companies in Botswana were struggling with manual inventory tracking, leading to errors, stockouts, and overstocks.

- Lack of Real-Time Visibility: Without real-time data, businesses couldn’t make informed decisions, resulting in inefficiencies and delays.

- Operational Inefficiencies: Traditional methods couldn’t keep up with the rapid pace of modern logistics, causing bottlenecks and increased labor costs.

- Integration Issues: The fragmentation of existing systems made it difficult to integrate with other business processes and technologies.

Solution: WMSOne best warehouse solution in Botswana

WMSOne is a suite of AI-powered business management solutions that enhance efficiency and intelligence in your operations. Our Products are tailored for businesses of all sizes, offering advanced capabilities to streamline and optimize workflows.

WMSOne addressed these challenges head-on with its comprehensive suite of features designed to optimize warehouse operations:

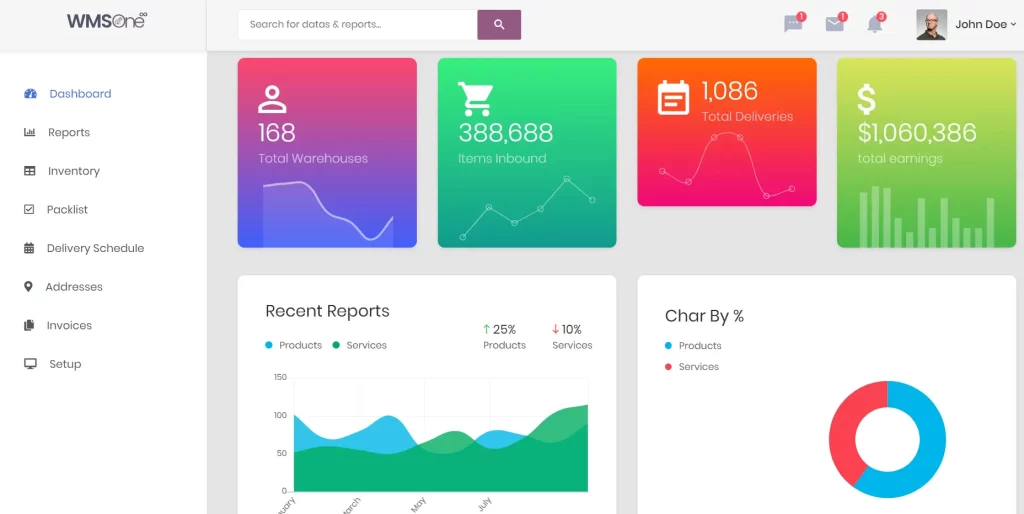

- Real-Time Inventory Management: WMSOne provided real-time tracking of inventory levels, locations, and movements, eliminating errors and ensuring optimal stock levels.

- Enhanced Visibility: With WMSOne’s advanced analytics and reporting tools, businesses gained complete visibility into their warehouse operations, enabling data-driven decision-making.

- Operational Efficiency: Automation of key processes such as order picking, packing, and shipping reduced labor costs and increased throughput.

- Seamless Integration: WMSOne’s ability to integrate with existing ERP systems and other technologies ensured a smooth transition and cohesive workflow.

Implementation

The implementation of WMSOne in Botswana’s warehouses is a game-changer. One notable example is Gaborone Logistics, a leading logistics provider in the country. Facing significant challenges in managing its growing inventory, Gaborone Logistics turned to WMSOne. The implementation process included:

- Initial Assessment: WMSOne’s team conducted a thorough assessment of Gaborone Logistics’ existing operations and identified key areas for improvement.

- Customization: WMSOne tailored its solution to meet the specific needs of Gaborone Logistics, ensuring a perfect fit for their operations.

- Training and Support: Comprehensive training sessions were conducted for Gaborone Logistics’ staff, ensuring they could effectively utilize the new system. Ongoing support was also provided to address any issues and ensure smooth operation.

Results

The impact of WMSOne on Logistics was nothing short of transformative:

- Reduced Errors: Inventory discrepancies were reduced by 80%, thanks to real-time tracking and automated processes.

- Increased Efficiency: Order processing times were cut by 50%, enabling faster fulfillment and improved customer satisfaction.

- Cost Savings: Labor costs decreased by 30% due to automation and optimized workflows.

- Scalability: Gaborone Logistics was able to scale its operations to meet growing demand without compromising on efficiency or accuracy.

Conclusion

WMSOne’s success in Botswana is a testament to its powerful capabilities and the significant impact it can have on warehouse operations. By addressing critical challenges and providing a comprehensive, customizable solution, WMSOne has established itself as the premier WMS in Botswana. Businesses across the country are now leveraging WMSOne to drive efficiency, reduce costs, and stay ahead in a competitive market. With its proven track record and continuous innovation, WMSOne will remain the leading warehouse solution in Botswana for years to come.

This case study showcases how WMSOne can transform warehouse management, providing a compelling narrative that highlights its strengths and successes in the context of Botswana’s logistics industry.