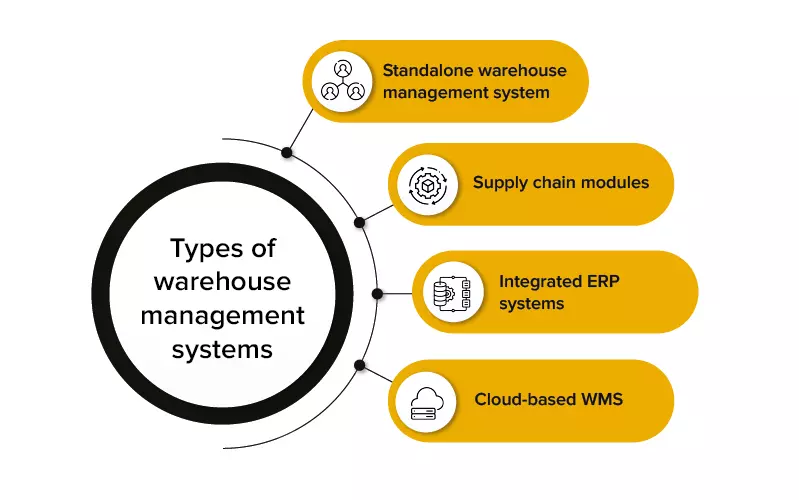

Different Types of Warehouse Management Systems

- Why WMSOne Stands Out In Warehouse Management - December 30, 2024

- The Future of Warehouse Inventory Management in 2025 - December 9, 2024

- Cold Storage Warehouse: Keeping Food Fresh And Safe - October 3, 2024

In the rapidly evolving world of logistics and supply chain management, understanding the types of warehouse management systems (WMS) available is crucial for optimizing operations and maintaining a competitive edge. WMS solutions come in various types, each designed to meet specific operational needs and challenges.

What is a WMS?

A Warehouse Management System (WMS) is a software solution designed to streamline and optimize all the activities that happen within a warehouse. It acts like a central nervous system for your warehouse, keeping track of inventory, storage locations, order fulfillment, and more.

We’ll explore the different types of Warehouse Management Systems, their unique features, and how to choose the right one for your business.

1. Standalone Warehouse Management Systems

Overview: Standalone WMS are dedicated systems that focus solely on warehouse management functions. These systems are ideal for businesses looking for a specialized solution to manage their warehousing operations without additional features.

Features:

- Inventory tracking

- Order picking and packing

- Shipping and receiving management

- Basic reporting and analytics

Pros:

- Cost-effective for small to medium-sized warehouses

- Easy to implement and use

Cons:

- Limited integration with other business systems

- May lack advanced features found in more comprehensive solutions

2. Supply Chain Execution Modules

Overview: Supply Chain Execution (SCE) modules are part of a larger suite of supply chain management tools. These modules provide a broader range of functionalities, including transportation management, order management, and inventory management.

Features:

- Integration with transportation and order management systems

- Enhanced inventory visibility

- Multi-warehouse support

- Real-time tracking and reporting

Pros:

- Comprehensive solution for end-to-end supply chain management

- Improved coordination between different supply chain activities

Cons:

- Higher cost and complexity

- Requires integration with existing systems

3. Integrated ERP Systems

Overview: Enterprise Resource Planning (ERP) systems with integrated WMS functionalities offer a unified platform for managing all business processes, including warehousing. These systems are suitable for large organizations with complex operational needs.

Features:

- Seamless integration with finance, HR, and manufacturing modules

- Advanced analytics and reporting

- Scalability to support business growth

- Centralized data management

Pros:

- Single platform for managing all business processes

- Enhanced data accuracy and consistency

Cons:

- High implementation and maintenance costs

- Requires significant time and resources to deploy

4. Cloud-Based Warehouse Management Systems

Overview: Cloud-based WMS solutions offer flexibility and scalability by providing access to warehouse management functionalities through the internet. These systems are ideal for businesses looking for cost-effective and easily scalable solutions.

Features:

- Remote access from any location

- Automatic updates and maintenance

- Subscription-based pricing model

- Scalability to adjust to business needs

Pros:

- Lower upfront costs

- Easy to implement and scale

- Enhanced disaster recovery and data security

Cons:

- Dependence on internet connectivity

- Potential concerns about data privacy and control

Choosing the Right WMS for Your Business

Selecting the right type of WMS depends on various factors, including the size of your business, the complexity of your operations, and your budget. Here are some tips to help you make an informed decision:

- Assess Your Needs:

- Evaluate your current warehouse operations and identify areas that need improvement.

- Determine the scale and scope of functionalities required.

- Consider Integration:

- Ensure the WMS can integrate seamlessly with your existing systems, such as ERP or TMS.

- Scalability:

- Choose a system that can grow with your business and adapt to changing needs.

- Budget:

- Consider both the initial investment and ongoing costs, including maintenance and upgrades.

- Vendor Reputation:

- Research vendors, read reviews, and consider their experience and customer support services.

Conclusion

Choosing the right WMS can be a game-changer for your warehouse operation. By understanding the different types of Warehouse management systems and their capabilities, you can select the one that best suits your specific needs and budget. With a WMS in place, you can say goodbye to warehouse woes and hello to a streamlined, efficient, and profitable operation.