The Role of Big Data in Supply Chain Management

- How Last-Mile Delivery Was Affected During Covid-19 - March 30, 2024

- WMSOne Invoicing SaaS vs Traditional Invoicing Methods: - March 29, 2024

- Integrating Invoicing Systems with WMS - March 27, 2024

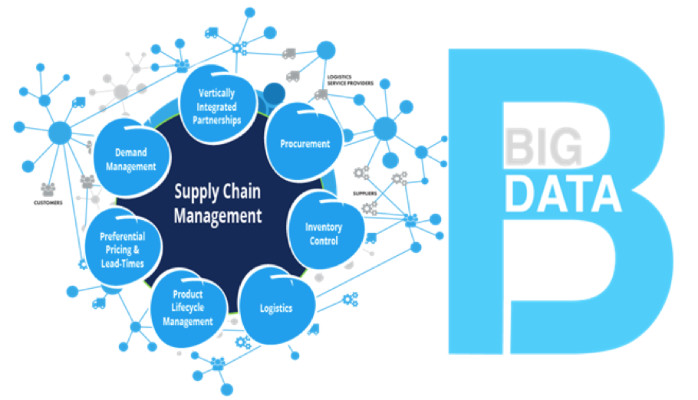

In today’s increasingly interconnected and digital world, the role of big data in supply chain management has become more pivotal than ever. As businesses strive to optimize their operations and stay ahead of the competition, leveraging big data analytics offers a strategic advantage that can transform efficiency, responsiveness, and innovation. Enter big data—a revolutionary force transforming how companies forecast demand, track inventory, manage suppliers, and mitigate risks. By harnessing the power of big data, organizations can achieve unprecedented levels of efficiency, agility, and customer satisfaction.

Understanding Big Data in Supply Chain Management

Big data refers to the vast volume of structured and unstructured data generated from various sources such as sensors, RFID tags, GPS devices, social media, transactional systems, and more. In the context of this, big data encompasses information related to procurement, production, transportation, warehousing, and customer interactions. The ability to collect, analyze, and interpret this data can provide valuable insights for making informed decisions and optimizing processes.

We’ll explore the significant impact of big data on supply chain management, highlighting key benefits, practical applications, and future trends.

Key Benefits of Big Data in Supply Chain Management

- Enhanced Visibility and Transparency

- Real-time tracking of goods and materials throughout the supply chain improves transparency and trust.

- Improved Demand Forecasting

- Analyzing historical sales data and market trends provides precise demand forecasts, reducing stockouts and overstock.

- Optimized Inventory Management

- Identifying demand patterns helps optimize stock levels, reduce carrying costs, and minimize obsolescence.

- Enhanced Supplier Performance

- Assessing supplier performance based on delivery times and quality helps build stronger relationships and negotiate better terms.

- Increased Operational Efficiency

- Identifying inefficiencies enables targeted improvements, reducing lead times and operational costs.

- Risk Mitigation

- Analyzing multiple data sources identifies potential risks, allowing proactive risk management.

Practical Applications of Big Data in Supply Chain Management

- Predictive Maintenance

- Predicting equipment failures through data analytics reduces downtime and maintenance costs.

- Route Optimization

- Analyzing traffic and weather data optimizes delivery routes, cutting fuel consumption and delivery times.

- Customer Insights

- Understanding customer preferences and buying patterns helps tailor products and improve satisfaction.

- Sustainability Initiatives

- Identifying opportunities to reduce environmental impact through data analytics promotes sustainable practices.

Future Trends in Big Data and Supply Chain Management

- Integration with AI

- Combining AI with big data for advanced predictive analytics and real-time decision-making.

- Blockchain for Data Security and Transparency

- Using blockchain to enhance data security and traceability in the supply chain.

- IoT Connectivity

- Increasing IoT device usage for deeper insights and precise monitoring of supply chain operations.

- Advanced Analytics Platforms

- Developing sophisticated platforms for easier processing and interpretation of big data.

Conclusion

Big data is revolutionizing supply chain management by enhancing visibility, optimizing operations, and driving informed decision-making. As technology evolves, integrating AI, IoT, and blockchain with big data will further transform supply chains, creating a more connected and intelligent future. Embracing these advancements will help businesses build efficient, responsive, and resilient supply chains.