Digital WMS Solutions: From Paper to Digital Solutions

- Why WMSOne Stands Out In Warehouse Management - December 30, 2024

- The Future of Warehouse Inventory Management in 2025 - December 9, 2024

- Cold Storage Warehouse: Keeping Food Fresh And Safe - October 3, 2024

Adopting a Digital WMS solutions revolutionizes warehouse operations by providing real time inventory tracking. Think about running a warehouse without computers. It sounds tough, right? Well, that’s how things were a long time ago! Let’s go back in time and see how warehouses went from using pens and paper to using digital solutions to make things easier and effective.

In today’s world, businesses are seeing the value of digital warehouse solutions. Digital Warehouse improves real time tracking of our inventories.

The Pen and Paper Days:

Every time something came in or went out of the warehouse, someone had to write everything down in a book. It was messy, slow and made a lot of mistakes, but it was all we could do at the time.

The Early Computer Days:

Then computers came along and things got a little better. In the 1970s and 1980s, warehouses started using simple computer programs to help with inventory. This was better than writing everything down, but these early computer systems were still a little difficult to use.

Advantages of Digital WMS over Traditional Warehouse Management:

Here are some reasons why digital WMS is often considered the best choice:

- Accuracy: Digital WMS minimizes the potential for human error that is inherent in manual systems. Barcode scanning and automated data entry ensure accuracy in inventory tracking, order fulfillment, and other warehouse operations.

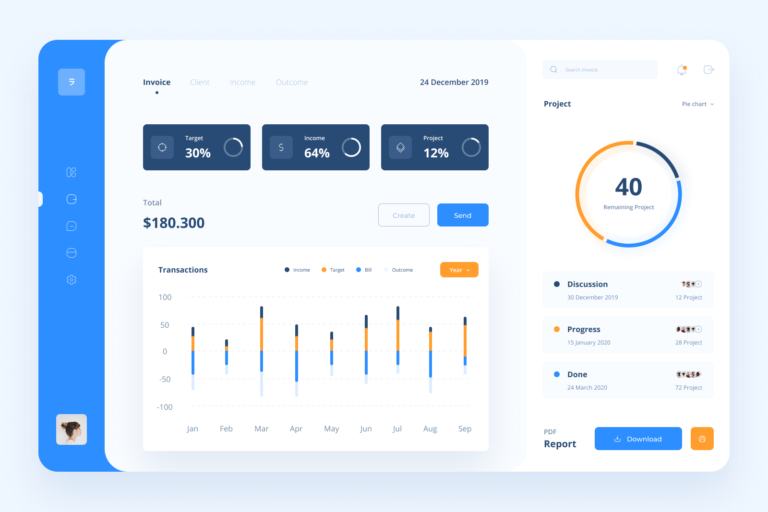

- Real-time Visibility: With digital WMS, managers have real-time visibility into inventory levels, stock movements, and order statuses. This enables better decision-making, as managers can quickly respond to changes in demand or supply chain disruptions.

- Efficiency: Automation features such as automated picking routes, inventory replenishment alerts, and batch picking optimize warehouse processes, leading to increased efficiency and productivity.

- Cost Savings: Digital WMS helps reduce operational costs by streamlining processes, optimizing inventory levels, and minimizing errors that can lead to waste or inefficiencies.

- Improved Customer Service: Faster order processing, accurate inventory tracking, and on-time deliveries result in improved customer satisfaction and loyalty.

Upgrade your Growth with WMSOne:

From writing in huge books to clicking on a computer screen, the way warehouses work has changed a lot. Thanks to technology, warehouses are faster, more accurate and easier to run than ever before. One thing is for sure, it’s great. Say goodbye to the old ways – the future of WMS is bright, bold, and full of possibilities!